Rotainer Archive & Capabilty Statement

| About CRS | Rotainer Celebrating 15 Years & Capability Statement

CRS Rotainer®

Archive

Capability Statement with Historic Overview

Concept to Completion

CRS, Arguably the Worlds most Vertically Integrated Manufacturer of

Container Rotation Equipment

(Condensed Version. Several recent projects, customer details with some locations omitted at the request of our clients)

Suppliers & Original Equipment Manufacturers (O.E.M) of

Container Rotations Systems - Heavy & Light Duty Open Top Rotatable Containers - Container Lids and Lock systems - Special High Volume Rotatable Containers - Lid Lifting System - Ezzeloaders - Specialised 20ft Spreaders - Container Tipplers - Mechanical Engineering Solutions - Electrical Engineering & Automation - Commissioning Services - Operators Training - Consultancy or Site Assessments - Heavy Duty Container Trailers - Container Spill Trailers

Brief History of CRS, the 'Then & Now'.

2009. How It Started

AMMESA - Australian Mobile Mining Equipment, Systems and Accessories Pty Ltd was commissioned by D.P.W South Australia to undertake an engineering review on modern day container rotators. Their (D.P.W) investigation revealed that, at the time, there was no current manufacturer or suppliers existing Globally.

The basic criteria was to source a local supplier to design and supply container rotators to cater for an influx of Mid Tier Mining Companies coming on line with their high value concentrates for export.

This concentrate was planned to be transported to the Ports in open top shipping containers for storage then unloaded directly to ships holds.

To meet D.P.W guidelines, the rotators would need to be approximately 12 tonnes in tare weight with the capability of lifting containers with a gross weight of 38 tonnes while complying to the engineering criteria of the latest Post Panamax STS cranes.

Historic container rotators (no longer available) manufactured in the late 70's 80's were flimsy and rudimentary in construction or had tare weights of over 22 tonnes, they needed longitudinal support arms to strengthen the main frame and where operated by low tech chain and sprocket drive systems, therefore a re-think was inevitable.

As specialised mining evolved, the opportunity was seized by CRS (formally AMMESA), the 'Rotainer®' brand came to fruition. I.P and the original brand 'Rotainer®' secured, registered and the World's first top lift, 360 degree container rotator was fully engineered and readied for production.

Below is an extract from Original enquiry from DPW, 1st April 2009

Dear All,

I need some help regarding pictures attached, we are trying to win a contract exporting bulk ore from the Terminal. The attachments on the crane that tip the container are not easy to find, does anyone know who or where they are made.

Click here to view

ORIGINAL_ROTAINER_SKETCHES_1_OF_4.pdf

2010. Rotainer Number 1. An Industry Game Changer

IMX Resources, an Australian Iron Ore Miner was the first company to take up this new technology with the initial Rotainer® H.D being installed at D.P.W's container terminal, South Australia. This was a big ask at the time as only 1 Rotainer® H.D was order to cater for handimax vessels of 70,000 DWT.

As the industry watched, the Rotainer delivered, it proved to be highly successful in this pilot programme with other opportunities in the pipeline coming to fruition not long after the first Rotainer® proved its worth in strength and reliability.

Furthermore, around this time Oz Minerals, an Australian premier copper concentrate mining company showed interested in this new technology. Their requirements was to use fully sealed containers with some form of automated lid opening mechanism.

During an independent compliance review and to meet latest environmental guidelines, it was discovered that Generic, 'off the self', open top containers did not meet the mechanical dynamics required at the D.P.W site, it became evident that their was a need for a purpose design, heavy duty, open top. rotatable container.

It was at this time, the Australian company Container Rotation Systems Pty Ltd was establish to fully focus on and developing this market segment.

Rotainer® 001 Being Commissioned Dec 2010, DPW, Adelaide

Rotatable Container Number 1. In 2009, early 2010, AMMESA/CRS went to the drawing board to design a fully certified, rotatable container for 38 tonnes gross weight that could be rotated by the top 4 twist locks, unsupported to meet the velocities of the latest Post Panamax Ship to Shore Cranes.

This innovative, Patent Protected container design offered the highest payload for tonnes of tare weight. This was achieved by a completely new container concept, fit for purpose and not by copying or modifying containers that had been used in the indusrty for many years prior to 2010.

The Very First Rotatable Container under construction for proto-type approvals 2009/10

Some Key Features of this total new design open top container. .

1. Clean flow corner gusset to minimise dust emissions.

2. Heavy duty comer pockets to allow 38.400kgs Gross weight without the need for container side wall supports.

2. End Wall moved inbound.

3. Rounded Bottom on the tub allows a 'Clean Pour' therefore no need for costly and problematic dust suppression systems.

4. Tapered walls.

5. Hemple low friction in internal paint.

6. 'Whale Bone Rib' design allow flex and strength for Rail, Road, Shipping and Industrial applications.

7. Hard Flat lids with automated lock systems with security tag receptacles.

8. Tapered top and bottom rails for easy decontamination in wash bays.

2011. CRS Invented and Installed the Very First Automated Lid Lifting System.

Oz Minerals ordered a Rotainer® H.D with CRS's newly developed automated lid lid lifting system. CRS Lidliftor® was the first automated lid lifting system for top lift container rotators in the the World, another CRS first. Fact!

The Rotorcon® Brand, (rotatable container) the World's First Purpose Design Rotatable Container was also introduced to the market around that time, this was another CRS milestone achievement in the development of the container rotation industry.

The industry continued to develop with many thousands of containers being handled by Rotainer® container rotators.

Mining Companies such as Oz Minerals, Cristal Mining, Hillgrove Resources all use the CRS Rotainer H.D to export their products through South Australian Ports.

Interestingly, after 14 years Rotainer® H.D, serial number 001 is still in full operation today, a testament to CRS quality products.

The very first automated lid lifting for container rotators being tested, Smithfield, Sydney

2012. First Ship Gear Rotainer® Delivered

1. Further evolution of the industry saw the need for a container rotator for generic 1450mm Half Heights containers. At the request of a Stevedoring Company based in Townsville, North Queensland and to meet clients needs for ships crane applications, CRS had to develop a unit that had a very light tare weight of 6000kgs with a maximum gross lift of 28,000.kgs. CRS developed the Rotainer M.D for ships gear. This lightweight unit was another 'World First' for the containerised bulk handling industry

To achieve these specification, CRS had to develop a new lightweight tubular steel frame structure with a new, unique, simple, hydraulic drive mechanism for 180 degree rotation. After a long period of research and development CRS released and Patented its own proprietary mechanical drive system, This system has been so cost effective and reliable it stays in continuous production.

CRS, Purpose Built, Light Weight Ships Gear for Generic Half Heights,WWL 26,000kgs gross weight.

2013 CRS invented the first to offer Variable Arm for Container Rotators

1. Variable Arms. To assist multi user berths where very often different products are handled, CRS designed, developed and Patented a variable arm system. This innovative development allows products with an S.G's ranging from around 750kgs per cubic metres (grain products in 2900mm containers) right through to very heavy concentrates such as lead in 1450mm Half Heights containers via the one Rotainer®.

This highly successful option has been taken up by many users and is available for our older Rotainer H.D's right through to the full Eurospec Range of container rotators.

Variable arm in final stages of installation on a Rotainer MH42. Change for 1450mm to 2900 container in minutes circa 2023

2. Food Grade Containers. Progress moved to the food industry with 3 units Rotainer® H.D being commissioned in Thailand. These units handled raw sugar in CRS specially designed high volume Maxitainer® container. This was a 3 crane STS operation, a highly successful operation, which consistently sets record loads rates 65,000 tonnes in less that 24 hours, No other container rotator supplier can make this claim.

CRS Supplies special container designs for cost effective local production. These food grade containers were made in Thailand under CRS's guidance.

2013. Eritrea, A Global Success for CRS.

Nevsun Resources approached CRS with a problem. Their Bisha Mine, Eritrea, situated close to the Sudanese Border, some 350kms from the Sea Port of Massawa was transitioning from Gold Bullion production to copper and zinc DSO export.(Direct Shipping Ore). The main highway has over 150 switch back corners, rises to an elevation of 2325m above sea level in just 120kms.

The plan was to containerise the ore concentrate and use a Rotainer® system for ship loading at Massawa Port.

After a 4 day trek from Australia to the Bisha Mine site, CRS management conducted a full route survey with consolidation of 15 years worth of consultants documentation and recommendations, following several meetings with Senior Government and Mine officials, CRS was awarded a full 'Turn Key' project of procurement, delivery, installation and commissioning of the complete concentrate handling from the Bisha Mine to the Massawa Port.

Several trips to Europe, China amongst other Counties saw the procurement of all the equipment with the successful arrival of all the machinery on site within the programed time frame.

CRS organisational skills saw a 600 tonne mobile harbour crane delivered to the Port, fully assembled and commissioned ex Rotterdam via a heavy lift ship, several hundred containers Ex China, Rotainers® and Ezzloadores® Ex Australia , Reach Starkers and Forklifts Ex Europe, arranged over 100 specially designed prime mover trucks and lightweight container trailers Ex China, all via CRS's input.

CRS had a team of 6 highly skilled staff on site for extend periods for assembly, commissioning with operational start up training.

CRS was, and still is the only one stop supplier capable of handling such a mammoth project as a single point of contact.

8 years on, CRS still fully supports their original supply with additional equipment as needed, spare parts and technical support, further testament to CRS industry experience, dedication, reliability and professionalism.

CRS with the Massawa Port Team

2013. The Design of the Very First Container Rotator for Reach Stackers

The Rotainer R.S (Reach Stacker) was developed at the request of a major CRS Rotainer® client. Their need was for a multifunctional container rotator that could be quickly deployed at any location for short or long term projects, it had to be self powered with remote control, be able to work under STS Crane, Mobile Harbour Cranes Reach Stacker and Ships Gear with a gross lift of 38,000kgs

To meet the required specifications, the recently patented, innovative, CRS hydraulic crank arm system was engineered into the basic Rotainer H.D steel structure. The result is a highly versatile '3 in i' container rotator, another 'World First' for the industry and CRS with several units operating in Counties such as the P.R.O.C (Peoples Republic of China)

AIMEX Trade Fair, Olympic Stadium, Sydney Australia. 2013

2013 Rotainer Europsec 38 with Automated Lid Lifting. This a 'Stand Alone' system so no need to interface with the Reach Stacker. Always tips away form the operator for complete safety (Same as front end loader operations)

2015. CRS Container Tippler Delivered

Chilean Copper concentrate producers, Codelco and Anglo American, the World Largest Copper Miners approached their Port Operators, Puerto Ventanas, Chile, with a view to increase export capacity, move away from using antiquated 'kibble' technology for transporting concentrates to a more modern 'Worlds Best Practice' closed container systems.

The feasibility review highlighted that to compete this upgrade would requiring an investment upwards of $20Mill USD in infrastructure upgrades. Limitations on available space amongst other things such as an established rail network made traditional containers rotator (Rotainer) systems unusable. CRS was contacted through its Chilean distributor Contekner, to review the application and look to offer an economical solution.

CRS, thinking out side of the square, proposed a completely new concept. CRS offered a fixed base 'ContainerTippler' system, elevated on stilts on a specially engineered frame structure some 10 metres above an established underground conveyor network. Containers would be lifted directly from rails cars, placed in the proposed 'ContainerTippler' with the lids automatically unlocked and removed by a purpose built, CRS design, 20ft container spreader prior to rotation.

After a lengthy review on competitive proposals the CRS concept was adopted and our engineering team set out to engineer a complete, 'turn key' container handling system for this particular project,

The complete tippler system successfully awarded to CRS. The system was then fully pre-fabricated in CRS's Sydney factory under the watch-full eyes of a Lloyd's Registered Representative. It was fully load tested for a period of time, disassembled, containerised and sent to Chile, South America for installation in the building by local contractor's.

Due to Chilean seismic conditions, the system had to be 'Earthquake' approved therefore, additional civil works were required to comply with local construction laws for structural footing reinforcement, this was also part of the CRS scope of supply. Analysis and engineering for this was undertaken in Australia with review and approval from local Chilean officials and Chilean Civil Engineers.

This project went together perfectly and without issues, delivered on time and within budget. Since installation, the CRS Static Tippler system has completed approximatey200,000 fully loaded rotations (over 6.5 Million Tonnes) with no major lost time occurrences or component change outs. This is further testament to CRS industry experience and capabilities.

Further to the above, the system required full automation. CRS sent an Australian Engineering team to site for several weeks to complete necessary electrical upgrades.

A very successful project and a Win Win for all involved.

CRS Static Tippler System with specialised container spreader including lid lifting. This unit is locatedChile, Latin America

2016. Taiwan - A new Destination.

A major milestone was achieved during this period with a complete Rotainer® R.S system being exported to the Peoples Republic of China. This equipment is used on a Liebherr Mobile Harbour Crane.

Rotainer® R.S's, Rotorcon® Containers, CRS Ezzeloadore® ans CRS Lidliftor® and Lidgripper® were exported to a major Stevedore to cater for high volumes of copper concentrate being imported from Latin America. This particular application involves breaking down large volumes of concentrates into smaller parcels then being blended in large sheds to the consistency required by the consumers, then re'loaded into ships for final delivery.

CRS was proud of this opportunity, to be able to export Australian manufactured products to China is reassurance of CRS quality and performance and an accolade in itself.

Specially Designed Rotainer H.D 3 in 1.

Ships Crane, Mobile Harbour Cranes, Reach Stackers

Stand Alone - Diesel Powered, Remote Control.

2017. Rotainer Eurospec is Born

Around this period enquiries were coming in from further afield, particularly the European region. A review of open top containers entering the market since the Rotainer inception clearly indicated ISO container loads of around 32 tonnes +/- were becoming the industry standard.

The question continually asked was 'Why are container rotators designs based on traditional 20/40 container spreader format?'

The answer was obvious. Traditional spreader manufactures found it easier to copy historic, obsolete container rotator formats or modify their general container spreaders rather invest in latest engineering techniques to come up with a new innovative, purpose design container rotators.

Reviewing latest innovative technology in the Mobile Hydraulic Crane and Mining industries, it became clear that single beam construction had a future for container rotators. CRS took this engineering technology and adapted it onto their container rotators.

CRS then set out to design, engineer and certify a completely new concept for container rotators with the following specifications,

1.Single, central beam construction that enclosed operating components internally to protect products being handled with consideration to environmental awareness.

2. Modulated in design, with options in heights and gross lifting weights from 32-38-42 tonnes.

3. It should be operated by either Diesel/Hydraulic or Electric/Hydraulic with all CRS standard operational options.

4. Automated lid lifting would be available on the machine as an option.

5. It must be able to work in hot, humid tropical regions up to +60c right down to areas with temperatures consistently below -20c.

6. Must be simpler in design with less moving parts compared to previous models.

7. Be abled to be transported globally by containerisation, pre-tested ex factory, ready to operate with assembly on site in less than 1 working day.

8. The 'one design' systems must work on a) Ships Cranes b) Mobile Harbour Cranes c) Ship to Shore Cranes d) Reach Stacker's.

9. Required be low in maintenance with any large moving bearings 'Sealed for Life'

10. To be the best quality, more reliable than any other unit on the market with a sell price lower than any comparative unit.

11. Preferably have, indusrty proved, 180 degree rotation to empty which offers reduced dust emissions with the capability of optional loading ships in N-S-E-W directions with the use of CRS's optional rotating head frames.

The CRS Rotainer Eurospec Range of Container Rotators came to fruition.

The First Rotainer Eurospec 32 Delivery to Beau Cameau, Qubec.

2018. Major milestones were achieved around this period.

Firstly, CRS Rotainer® progressed to another Country with a major Canadian Stevedore taking up the first Rotainer® Eurospec 32 for Ships Gear. The location for this particular operation was at Beau Comeau located 500kms North of Quebec City.

After several trips to site by CRS management, the specifications where finalised for Rotainer Euospec 32 fitted with CRS's 'Artic Pack'. which allowed our Diesel/Hydraulic system to operate at -20c for continuous periods. This was a Comalco operation therefore our Rotorcon® Heavy Duty 1800mm high containers were specified for the project due to the superior design and strength in the most extreme weather conditions.

Both the Rotianer® and Rotorcon® containers were subject to blizzard conditions during commissioning to prove their operating capability the most extreme weather conditions.

CRS Rotainer Container in -40C Blizzard Conditions

Anther highly successful project for the CRS team.

Secondly, Lend Lease, one of World Largest Construction and Management Companies, faced a problem at the new 'Star City' Casino construction project that was about to commence at Barangaroo, Darling Harbour, Sydney, Australia. At the time of commencement it was the Southern Hemispheres largest construction project.

To meet financial and development deadlines with a view to bring the construction of this prestigious building to completion on time, Lend Lease undertook a feasibility review on a different approach to,

a) Undersea contaminated sub-soil,

b) Transportation of highly toxic spoil,

c) How to implement their new 'Buld up - Build Down' construction methods.

CRS was approached to review a solution with the project consortium. Combined consultation with Lend Lease's Civil Contractors, CRS offer a solution to develop a specialised underground container loading system. Sealed containers were to be loaded several floors below sea level, elevated to ground level via 2, purpose built, overhead gantry crane structures then transported to an E.P.A, environmentally approved contaminated waste facility.

CRS Wastetainer® Sealed Cotainer Solutions

CRS also developed a new Rotainer® Eurospec 32 specifically for the project to be uses on Reach Stacker's. This involved over 60 truck movements 6 days per week for over 18 months. This phase of the underground works completed on time and within budget.

Furthermore to meet State Government and Road Transport Regulation on "Risk Mitigation' in the event of a vehicle accident or, in worst case scenario, a truck roll over, CRS developed a new, innovative, container lid locking system that positively locks the lid of an open top container firmly in place.

This project was so successful many environmental and industry awards and accolades were forthcoming, Global interest in this new CRS's newly patented technology is on the increase with further projects to come on line for CRS in the not too distance future.

CRS is proud of the fact that they are the only supplier in the container rotation industry that could offer Lend Lease such a simple solution for a complexed problem.

CRS was proud to part of this project by offering an innovative solution to such well respected, globally based, High Profile Construction Company such as Lend Lease and Crown Casino.

CRS Developed and implemented a sealed container system for contaminated waste removal at the Crown Casino site, Sydney Australia

2019. Europe Opens up for CRS

2. New European markets open up for CRS. Lithuania, for food grade products and Russia for Coal and Scrap metal.

Lithuania was a food grade loading operation utilising a CRS Rotainer® Eurospec 38 upgraded to use with Rotorcon® 2900mm heavy duty containers. A CRS head frame was specially adapted so that CRS newly developed, innovate 'E Link', low centre of gravity hook connection could be utilised to allow for quick connection to either Liebherr or Gottwald MHC's.

St Petersburg Russia saw installations for Scrap metal loading and other another high volume Coal Export Terminal at Ulst Luga, one of Russia's largest bulk export region.

The scrap metal operation saw the release of CRS's 2900mm Scraptainer®, a highly modified CRS Rotorcon® container catering to the rigours of handling large volumes of scrap metal fast and efficiently making their current skip bin system antiquated and ineefective..

CRS Scraptainer® being readied for dispatch

Ulst Luga. CRS was offered an opportunity to participate in a Coal operation that would involve the updating of 4 units, 10 year old Kone STS cranes. CRS's customer, having recently received a contract to load approximately 2 Million tonnes of coal in a short period would be offered additional contracts provided the CRS Rotainer System met the delivery rates as promoted.

The clients current method of operation was a large skip bins operation that just did not meet the outputs required. CRS, through their local agent offered the Rotainer solution which proved to be highly successful.

35 to 40 container movements per crane was the criteria CRS had to comply with to be awarded the project. To enhance the client expectations and loading rates, CRS offered to develop a special, electronically managed, rotating head frame that would allow for N-S-E-W discharge which dramatically increases loading rates.

CRS's solution was 4 unit set up of Rotainer Eurospec 38's, with rotating head frames with CRS's Coaltainer®, 2900mm heavy duty container. After a lengthy appraisal of competitive equipment, CRS was offered the supply for this project, furthermore, the client required a one source of supply, one source of responsibility procurement process, something only CRS can offer.

The project had been running successfully for just on 2 years, sometimes in blizzard conditions down to -28c

Simple facts after 2 years of service.

1 Rotainer Eurospec 38 has completed 39,000 cycles with no major component change-outs or lost time breakdowns.

Realistic average container loads 28 tonnes= 1,092,000 tonnes Coal loaded per Rotainer.

7000 cycles per CRS Coaltainer® = 3500 cycles per year.

CRS knows of no other, Open Top, High Cube Containers to have completed this amount of cycles in such a short period of time, a record in any-ones account, further testament to the quality of CRS's well designed, well engineered, high quality products. A remarkable return on investment for the purchaser.

Rotainer Eurospec 38 with CRS's Specially Designed N-S-E-W rotating spreader system

Dramatically Reduces Trimming Time.

2020. A New Decade - New Challengers - A different World - Alternative Approach

As Covid 19 took its toll on the World, life continued, albeit slowly, with a number of pre-Covid projects coming on line. New challengers with a re-think of the way things were done bought the best of innovations out in many companies whilst some remained stagnant.

Higher Capacity Equilibrium cranes offering new technologies in mobile cranes with greater performance were entering the traditional Mobile Harbour Crane market. A well respected Port Operator asked CRS to provide a competitive offer against several other suppliers of Container Rotators.

Considering 90% of the World's open top container are handled by Mobile Harbour Cranes, reviewing the potential uptake on these style fixed boom Equilibrium Cranes, CRS engineering team believed it was time for a re-think on these style attachments for such high performance. fixed boom cranes.

CRS reviewed the clients contractual requirements on anticipated loading rates.

We also looked at the dynamics of equilibrium cranes combining CRS 13 years of container rotation knowledge, CRS was convinced that traditional container rotators using slings or chains to attach to the hook would not deliver the load rates anticipated.

CRS's application review offered the port operators a completely New Concept in single beam container rotator design.

The client embraced this new technology whole heatedly and promptly placed orders after concept presentation.

From this the Rotainer Eurospec 42MH came to fruition. (MH-Materials Handling)

The client was so impressed with the Rotainer MH, additional orders were forthcoming soon thereafter, some with CRS innovative, Patented, Variable Arm System which allows the one Rotainer to cater to various heights in open top container from 1450mm to 2900mm.

Another of CRS's 'Worlds First' for forward thinking, innovative design in container rotator technology, a proud industry achievement for CRS. From Concept to Completion ready for export in only a few months.

Rotainer MH range of Container Rotators - Now with 3 Option Drive Systems

180 Degree Hydraulic Cylinders - 360, Super Fast Bevel Drive Gearbox - 360 Mediuam Speed Slew Ring

2021. Technological Advancements Due to Covid Restrictions

As the Covid crisis was coming to end pre-covid enquires were starting to accelerate. Pipeline projects that were put on hold began to move forwards.

Supplier issues caused delivery delays many interested parties accepted the fact that to meet post Covid uptakes early placement of equipment orders were necessary

2021 also saw another proud milestone was the delivery of our highly sought after Rotainer Eurospec 38 R.S (Reachstaker) into mainland China. To facilitate a smooth transition into this emerging market combined with Border closures the CRS team introduced further new technology into our product portfolio which included the following;

1. ISG = Innovative Second Generation Electronics, simpler to install, easier to service.

2. CSS = Container Support System allow use of standard, open top, general purpose containers

CRS is constantly looking outside of the square to come up with innovative products to add to our extensive range of optional equipment. CSS allows our client to use general G.P container with the roofs cut our for rotation purposes..

3. RRM = Rotainer Remote Monitoring app. Allows remote access by the O.E.M for instant fault diagnostics and programming.

4. Maxibeam® (Patent Pending)= Maximisation is the key when it comes to efficiencies and profitability. With the advent of large transport capacities the boundaries are being pushed with general container handling capabilities. One of CRS's valued clients had a problem to solve.

Our clients current reach stackers are rated at 45 tonnes gross lift capacity, with a Rotainer fitted the gross lift required was 48 tonnes. Larger reach stackers are very expensive and are least a 12 delivery at best.

As 20ft containers were the only size to be handled there was no requirement for a 20/40 container spreader.

O.E.M's were approached to offer solutions on how to reduce spreader weights but all efforts were met with negative responses.

CRS engineering team took on the challenge to design, manufactures and certify a fixed 20ft spreader for dedicated Rotainer Reach Stacker operations. CRS's mining background allowed us to come up with a 'quick release' optional tool for reach stackers.

2022. More Innovative Products

2022 saw the release of our innovative, high capacity food grade containers. These large containers cater for the 'High Volume - Low Value' segment of the containerised bulk handling market. With cubic capacities of 55 cubic metres makes CRS's innovative design the the largest 20ft container by volume,currently available for container rotators.

contact sales@rotainer.com for more info on this Patent Pending innovative container

The latest addition to the Rotainer® portfolio is our new, single beam, 360 degree, multi directional container rotator. For some time CRS engineering team has been working on a high capacity slew ring drive system which would allow the full 360 degree rotation in 20 seconds with a single hydraulic drive motor on each side inkeeping with the CRS design philosophy of 'Kiss' Keep it simple silly'

Dana Australia a was able to engineer a special system to meet CRS requirements, a heavy duty, high speed motor with safety brakes that works with our current Electo/Hydraulic power packs. the result Rotainer® Eurospec 360PC.

A Custom designed Rotainer Eurospec 360PC with a hopper sealing system for total environmental awareness.

2023. Innovation Continues

1. Mulitlid™, An Industry Game Changer.

As more and more open top containers enter the market with different lids and lock options, to consolidate it place as the market leader in innovative Containerised Bulk Handling technology, CRS and its customers saw a need for a multifaceted lifting system that will work with any container lid system.

CRS developed and applied for a patent on lid system that has several lid unlocking systems on the one lid lifting beam.

At the flick of a switch you can move from one style of container lid to another, brilliant for negating patent issues currently involved in this industry.

2024. Celebrating 15 Years, New Procucts, A Big Year with Big Challenges.

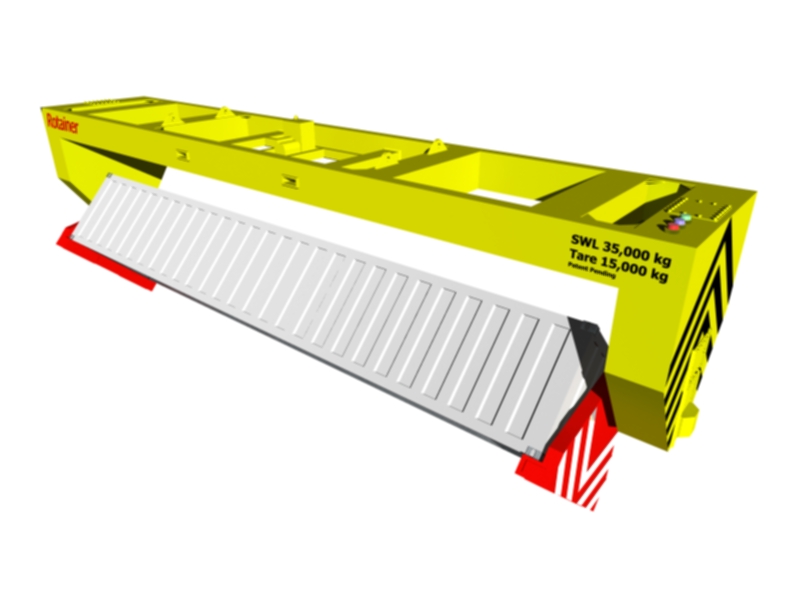

1. Big is Better - Rotainer® Euospec MH4240, 42 tonnes for 40ft containers.

First conceptualised in 2009 when we where planning on how to innovate the Containerised Bulk Handling industry, we look at rotator for a 40ft open top containers, the reality was this large machine would only be suited to high volume low value products such as Wood chips, pulps and waste products.

15 years on, we got serious, we have an enquiry from a long standing CRS customers, the net result is we are now producing an innovative 40 container rotator that can be shipped in 2 modules by containerisation.

This new Rotainer® has several pick up pints as standard for STS (Ship to Shore Cranes) and 20ft ISO point for Reach Strakers or 20/40 container Spreaders.

Electric or Diesel power packs offered with 360 degree multi-direction rotation with RRM (Rotainer® Remote monitoring) as standard.

2009/2010 40ft Rotator Concept with early Container Design

2009/2010 40ft Rotator Concept with early Container Design

2024 Latest Concept Graphics, currently in Production